Latest update 14 January 2007

Description

of APH-5 helmet from NAVPERS 10358-A, Parachute Rigger 3 & 2 from

around 1960

Article from Naval Aviation News, June

1956

Article from Approach, January 1957

Group discussions

The APH-5 helmet was the result of more than two years studies conducted 1954-56 for a successor to the H-3 and H-4 series of helmets. VX-3 at NAS Atlantic City, the Aero Medical Branch of Service Test Division at NATC Patuxent River, Air Crew Equipment Laboratory, Naval Air Materiel Center, Philadelphia, and AirLant and AirPac Fleet units were among those who coorporated with the Airborne Equipment Division of BuAer in testing the gear. The studies and helmet development work included with the MSA-N2 design, an immediate predecessor of the APH-5, being manufactured in very limited quantity. Another contract initiated work on an individually fitted (custom fit) helmets, designated the BBC and BBC-X2.

Far left: Although unconfirmed, this helmet is thought to be the BBC-X2; one of the designs studied in the process

that lead to the APH-5 helmet. It is characteristic by having a visor that retracts inside the helmet shell, much like

the visor design used the the French company Gueneau later on. Left: This DH-5-3 helmet was Gentex' bid for a

successor to the H-4 helmet but it was a MSA design, the APH-5, that won the competition. Right: A pilot at Naval

Air Materiel Centre wearing an APH-5 prototype helmet. This picture was taken as early as 26 October 1954, docu-

menting the long development process that lead to the service introduction of the helmet 18 months later. Far

right: A 1957 picture showing a pilot on a multi-engine aircraft wearing an APH-5. This was very early since the

stated policy was to equip fighter and attack squadrons first. Pictures © Bloodhound, Gentex, US Navy and unknown.

Production and entry into service

Initially, the APH-5 was designed without a visor, and the incorporation of a visor

required a cover plate in order that the helmet shell itself would not be weakened by the

visor guide slot. The final version was field tested for nearly a year by squadron pilots,

during which time some 50 helmets had an average of 300 flight hours logged. From the

comments and suggestions thus obtained, several modifications were made and the helmet was

put into production.

Far left and Left: Early

APH-5 helmet with an A-13A oxygen mask attached with Y-yoke. Right:

Close-up of the

stepped lock knob typical to some early APH-5 helmets. Far right: The

original sponge rubber lining which caused

heat build-up and collected perspiration. Pictures © unknown and Alan Masengale (lock

knob close-up).

The distribution of the APH-5 helmets began in April 1956, the first going to fleet squadrons as allocated by ComAirLant and ComAirPac. The first two contracts (2500 under first contract, 2500 under second contract for 7500) had been delivered by February 1957 allowing the helmet to become standard equipment in all fighter and attack squadrons as originally intended. As the years passed and more helmet became available they were issued to flying personnel from other squadrons as well.

Shortcomings

The APH-5 design was ground-breaking and set the standards for the vast majority of US

flight helmets until the advent of the HGU-55 in the early 1980s. It did however suffer

from a number of shortcomings, some more serious than others. From the beginning the APH-5

was suffering from heat built-up. The close fitting sponge rubber lining produced more

heat than the old cross-strap webbing of the H-3 and H-4. An associated problem was that

the sponge rubber collected perspiration in an unsatisfactory manner. Improved,

leather-covered liner pads were therefore introduced. Another frequent complaint about the

early helmets was that the visor lock button have been received -the binding problem was

solved in later models by the use of a template for aligning the track before riveting,

and by burnishing the visor track to reduce friction. The first 1500 helmets manufactured

had a plastic female communications plug on the left side of the helmet. It turned out

that it was poorly placed and subject to frequent breakage so later models had a lead-in

extending from beneath the edge of the helmet.

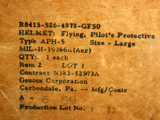

A wonderful series of pictures showing a factory-fresh APH-5

helmet made by General Textile Mills (later Gentex).

The upper, far left picture shows all contents of the original shipping box with fitting

pads, measuring tool and user

instructions. The lower, far right picture shows the print on the shipping box, telling us

that the helmet was manu-

factured in May 1959. Pictures © J.

Miller / Vintage Wings

Poor helmet retention

Poor helmet retention was the APH-5's most serious problem by far. In a time period of 12

months in 1958-59 there was a total of 52 cases of APH-5 loss during aircraft accidents in

the US Navy. Of these 52 cases, 50 percent were fatal while an additional 23 percent had

head injuries. Comparable figures for 1963 show 23 cases of APH-5 loss, with 48 percent

fatal injuries and 26 percent non-fatal head injury. Retention in the APH-5 was

accomplished by a nylon chin strap, nylon nape strap, three sizing pads of leather covered

foam rubber situated in the front, top and rear, and by ear pads of foam rubber attached

to polystyrene earcups.

The foam rubber composition of the sizing pads permitted

very small loads to compress the pads completely. In case of compression of the front

sizing pad, the nape strap lost contact with the head and became completely useless. In

case of compression of the top pad the slack created in the chin strap made it

ineffective.

Both the chin strap attached to the outside of the helmet and the napestrap had very

limited skin contact and therefore very little retention capability, even before sizing

pad compression, even if the straps were tightened to the point of intolerance for

prolonged wear.

The earcups were attached with a screw through the helmet shell, but the screw was only

fixed to the polystyrene earcup by a small fixture embedded in the foam. Even a small

impact would fracture the polystyrene earpad; and when this occurred, most of the

retention capability of the helmet was destroyed. Even if the polystyrene material

remained intact, the soft foam rubber earpads were compressed very easily, impairing the

retention capability.

Comfort

The APH-5 helmet was heavy and therefore uncomfortable to wear for longer

periods. It weighed 4 pounds with Hardman receivers but without oxygen mask. In comparison

an APH-6 helmet weihed only 3 punds 13 ounces. Some of the factors affecting the weight

were the heavy rubber edge beading, large earphones, and fibreglass visor housing. Other

factors adversely affecting comfort were problems with heat retention (even with the newer

fitting pads), abrasive chin and nape straps, and difficult fitting due to only two helmet

sizes available.

Oxygen mask attachment

The APH-5 went through several upgrades in order to improve oxygen mask

retention. Originally the helmet was issued with leather oxygen mask tabs with two male

studs on each, and the A-13A oxygen mask was attached using a Y-shaped metal yoke with

webbing straps. It quickly proved to be inadequate so the Hardman retention system, or

"Christmas tree" oxygen clip, were evaluated in 1957 and approved for use. The

oxygen mask clip could be quickly inserted in a slot receptacle on either side of the

helmet for a comfortable fit and a quick disconnection. Another step was taken when the

Navy adopted the self-aligning Sierra type 345-30 oxygen mask receivers by 1961. The

system retained the Hardman hardshell but introduced a new type of T-shaped bayonets,

easier to insert and release.

Far left: The original oxygen mask

attachment with the Y-shaped yoke, and webbing straps fastened with studs

to leather oxygen mask tabs. Left: APH-5 helmet with Hardman oxygen mask

receivers. Right: A-13A oxygen mask

with Hardman hardshell and the so-called Christmas tree bayonets that match the Hardman

receivers. Far right:

APH-5 with Sierra type 345-30 self-adjusting receivers and T-bayonets. Pictures ©

Chameloon, Shark, t5i6m60 and

Jukka 'JJ' Juutilainen.

Despite all the problems and shortcomings mentioned above, the APH-5 was used extensively throughout the 1960s even if its successor, the APH-6, was fielded around 1961. The APH-5 was modified with new fitting pads, new oxygen mask attachment systems, the chin strap was moved inside the helmet shell, and both chin and nape straps were fitted with cotton covered urethane pads for improved comfort. Some APH-5s were even modified with APH-6 type headsets with the well-known external disc.